Liyang Machinery: Lathe Titans

In the high-stakes world of industrial manufacturing, where tolerance margins are measured in microns and uptime is critical, CNC Heavy Duty Lathe Machines stand as the backbone of precision engineering. Among the elite CK6180 Lathe Manufacturers, Liyang Machinery emerges as a trailblazer, leveraging China’s manufacturing heritage to deliver custom-engineered CNC lathes that redefine the boundaries of metalworking speed, accuracy, and reliability.

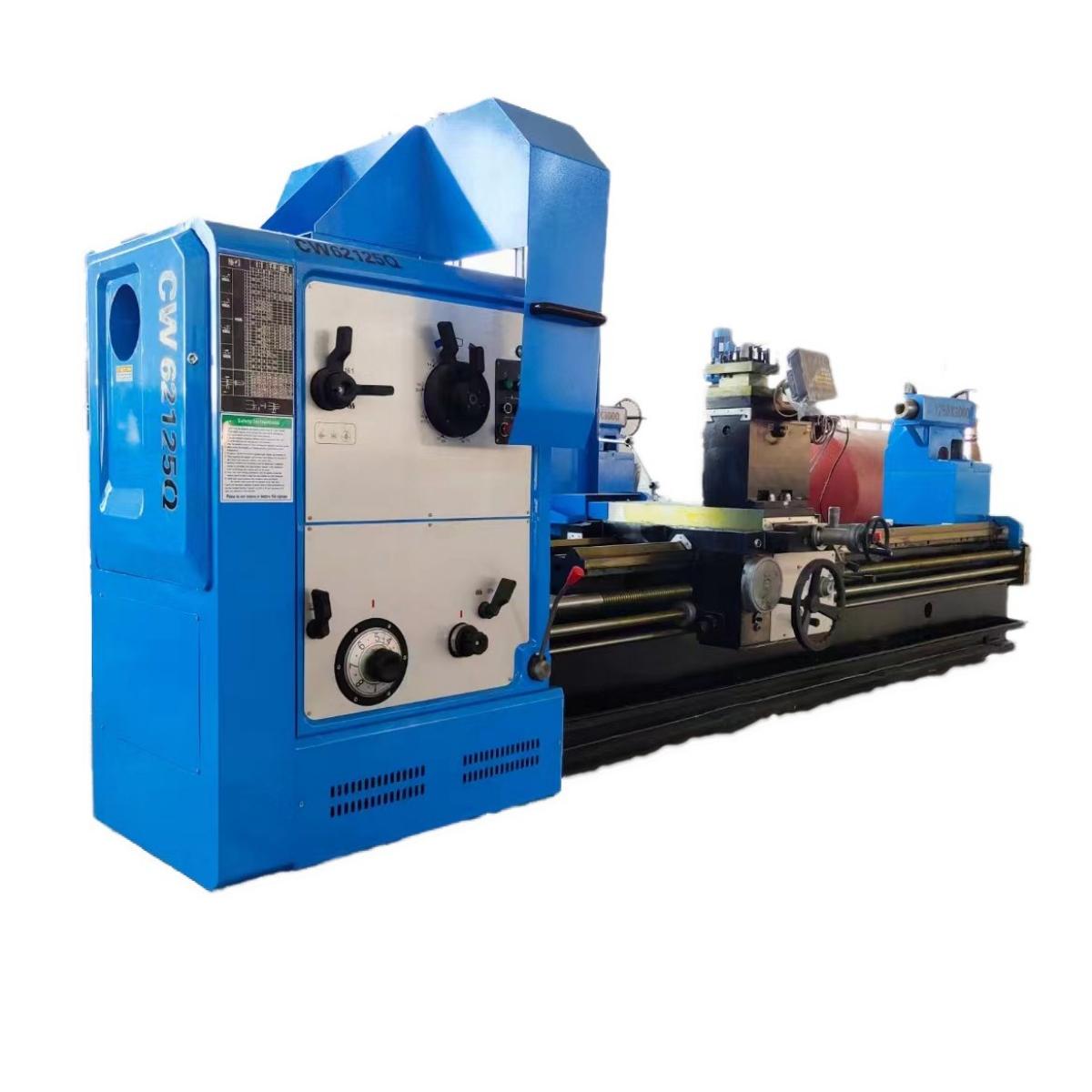

As a leading CNC Lathe Machine Manufacturer in China, Liyang Machinery specializes in crafting robust, high-torque turning centers designed to tackle the toughest materials—from hardened steel to exotic alloys. Unlike generic lathes that falter under heavy cuts or prolonged use, Liyang’s CK6180 series integrates rigid cast-iron beds, oversized spindle bearings, and servo-driven tool turrets to ensure flawless performance even in 24/7 production environments. This focus on durability has made Liyang a trusted partner for aerospace, automotive, and energy-sector clients demanding zero-defect machining.

What truly sets Liyang Machinery apart is its unwavering commitment to customization. Recognizing that every workshop has unique workflows, material requirements, and automation goals, the brand offers precision metal lathe custom solutions tailored to client specifications. Clients can collaborate with Liyang’s engineers to configure spindle speeds (up to 3,000 RPM), chuck sizes (8-inch to 15-inch), or even integrate Industry 4.0 features like IoT monitoring, predictive maintenance, and AI-driven process optimization. This bespoke approach has positioned Liyang as a preferred supplier for R&D labs, job shops, and Tier 1 suppliers seeking a competitive edge.

China’s manufacturing ecosystem provides Liyang with unparalleled access to advanced CNC controllers, ball screws, and linear guides, enabling the brand to achieve nanometer-level positioning accuracy. The CNC heavy-duty lathe machines produced by Liyang undergo rigorous testing for thermal stability, vibration damping, and geometric precision, ensuring compliance with ISO, DIN, and JIS standards. Additionally, the brand’s use of energy-efficient motors and recyclable coolant systems reduces operational costs and environmental impact.

Innovation is another cornerstone of Liyang’s philosophy. By integrating hybrid machining capabilities—such as live tooling, Y-axis milling, and sub-spindle operations—into its CK6180 lathes, the brand enables one-and-done part completion, eliminating secondary operations and reducing lead times. For example, Liyang’s custom precision metal lathes can drill, thread, and contour complex components in a single setup, boosting productivity by up to 40%.

Beyond product excellence, Liyang Machinery excels in customer-centric service. As a China-based manufacturer, the brand maintains a global network of technicians, spare parts warehouses, and training centers, ensuring seamless after-sales support. Clients also benefit from Liyang’s flexible payment terms and modular upgrade paths, allowing them to scale capacity or add features as production needs evolve.

For manufacturers seeking to supercharge their turning operations, partnering with Liyang Machinery means accessing a partner that combines Chinese manufacturing scale with Swiss-watch precision. The brand’s ability to craft custom CNC heavy-duty lathes—backed by decades of gear-cutting and spindle-design expertise—ensures machines that are not only workhorses but also catalysts for growth. In an era where efficiency and flexibility dictate success, Liyang’s lathes prove that innovation is the art of transforming metal into mastery.

Choose Liyang Machinery—where Chinese engineering meets global demand for smarter, faster, and fiercely reliable CNC turning solutions.