Liyang Machinery: CK6180 Pioneers

In the world of precision manufacturing, where durability and versatility are non-negotiable, Liyang Machinery has carved a reputation as a trailblazer in crafting industrial-grade turning solutions. Specializing in the CK6180 CNC lathe—a heavy-duty workhorse engineered for high-volume, high-precision machining—Liyang Machinery stands as a leading CNC turning machine manufacturer and custom industrial lathe supplier, catering to global manufacturers across aerospace, automotive, energy, and defense sectors.

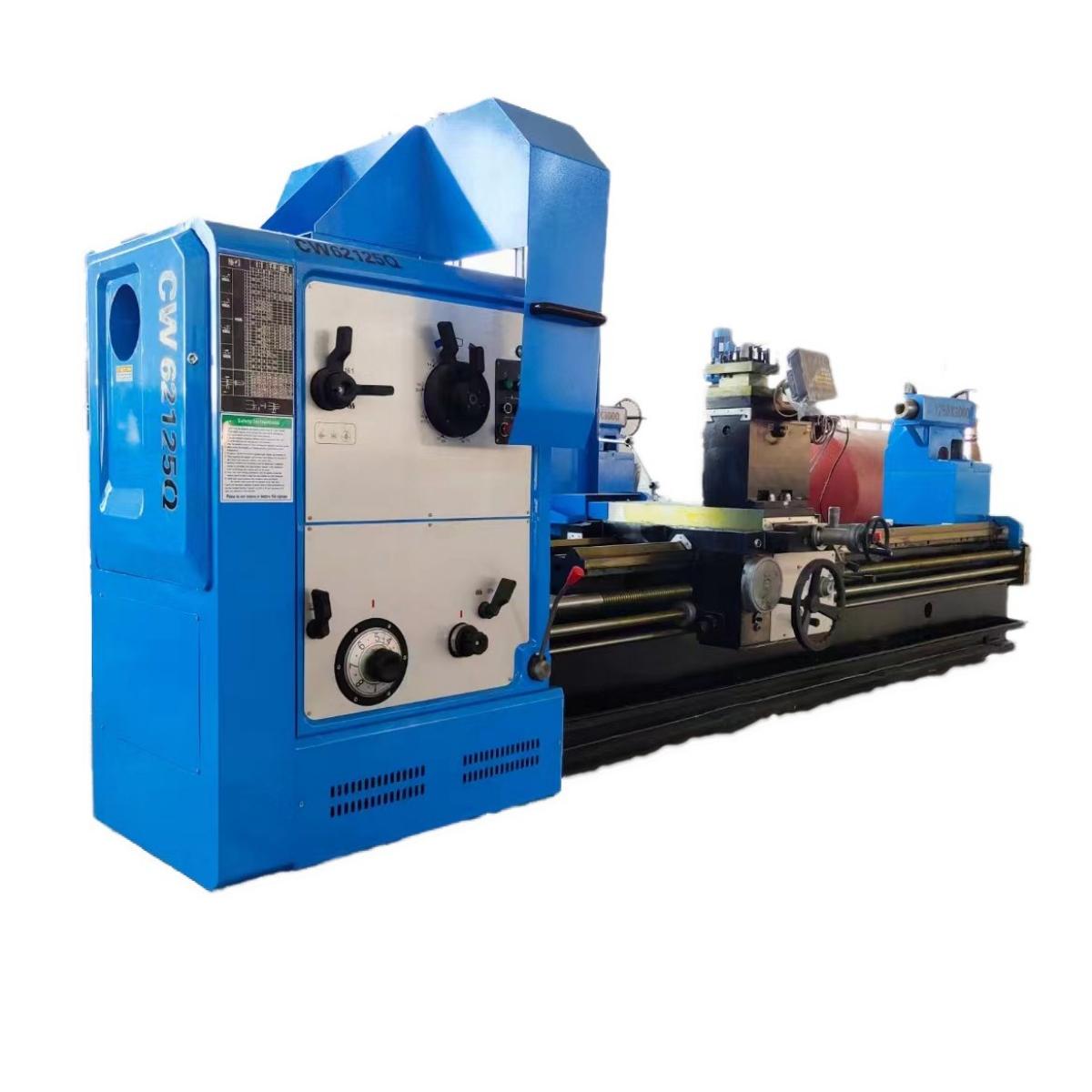

At the core of Liyang Machinery’s lineup is the CK6180 CNC lathe, a testament to robust engineering and cutting-edge automation. Built to handle diameters up to 800 mm and lengths of 2,000 mm, the CK6180 combines a rigid cast-iron bed with linear guideways and a servo-driven 12-station tool turret, enabling seamless turning, drilling, threading, and grooving operations. Powered by Fanuc, Siemens, or GSK CNC systems, it offers a spindle speed range of 30–2,000 RPM and a rapid traverse rate of 24 m/min, ensuring efficient production even for complex workpieces. For manufacturers seeking a balance between throughput and accuracy, the CK6180 delivers sub-0.01 mm tolerance levels, making it ideal for shafts, gears, and hydraulic components.

As a heavy-duty machine lathe innovator, Liyang Machinery leverages decades of expertise in China’s machine tool manufacturing hubs. The brand’s 120,000 sqm factory in Jiangsu Province employs advanced CNC milling centers, laser cutters, and robotic welding systems to produce lathes that meet ISO 9001 and CE standards. Unlike mass-produced alternatives, Liyang’s CK6180 undergoes rigorous dynamic balancing, thermal compensation testing, and vibration analysis before leaving the factory, ensuring minimal downtime and extended service life for clients.

What truly distinguishes Liyang Machinery is its prowess as a custom industrial lathe supplier. Recognizing that global manufacturers have unique requirements—from oil country tubular goods (OCTG) threading to hybrid electric vehicle (HEV) component machining—Liyang’s engineering team collaborates with clients to tailor CK6180 specifications. Whether it’s integrating custom spindle bore sizes, adding live tooling for mill-turn operations, or retrofitting automation cells for lights-out production, Liyang transforms standard lathes into bespoke solutions. The brand’s modular design approach allows quick adaptation to changing production needs, reducing lead times for custom orders by up to 40%.

China’s machine tool manufacturing ecosystem is the backbone of Liyang Machinery’s capabilities. The brand’s strategic partnerships with domestic component suppliers—including HIWIN linear rails and Yaskawa servo motors—enable cost-effective customization without compromising on quality. Liyang’s in-house R&D center, staffed with 30 engineers holding master’s degrees in mechanical engineering, continuously innovates to integrate Industry 4.0 technologies like IoT monitoring and predictive maintenance into its lathes.

For global partners, Liyang Machinery offers a turnkey experience, from factory acceptance tests (FATs) to on-site installation and operator training. The brand’s 24/7 technical support network, spanning 30 countries, ensures rapid response to maintenance needs, while its spare parts inventory guarantees 98% availability within 48 hours.

In an era where supply chain resilience is critical, Liyang Machinery’s agile manufacturing model allows it to scale production for sudden demand spikes, such as those seen in the renewable energy sector. The brand’s commitment to sustainability includes recycling 95% of production waste and offering energy-efficient spindle motors as standard.

Whether you’re a Tier 1 automotive supplier, an oilfield services firm, or a defense contractor seeking mission-critical precision, Liyang Machinery delivers—where every CK6180 is a pillar of strength, and every custom solution is a seal of excellence.

In a world where manufacturing is redefined, Liyang Machinery stands as a guardian of precision, empowering industries to turn challenges into opportunities with confidence. Trust in Liyang Machinery—where every lathe is a legacy, and every partnership is a partnership sealed in durability.