CK6150 CNC: Liyang Precision

In the realm of precision manufacturing, where efficiency, accuracy, and versatility are non-negotiable, the CK6150 CNC lathe machine stands as a cornerstone for workshops, OEMs, and industrial facilities worldwide. As a leading China-based manufacturer and supplier, Liyang Machinery has honed its expertise in crafting dual spindle CNC lathes that redefine productivity, enabling businesses to streamline operations, reduce cycle times, and elevate part quality. With a focus on innovation, customization, and global accessibility, Liyang Machinery has emerged as a trusted partner for clients seeking reliable, high-performance automatic CNC lathe solutions.

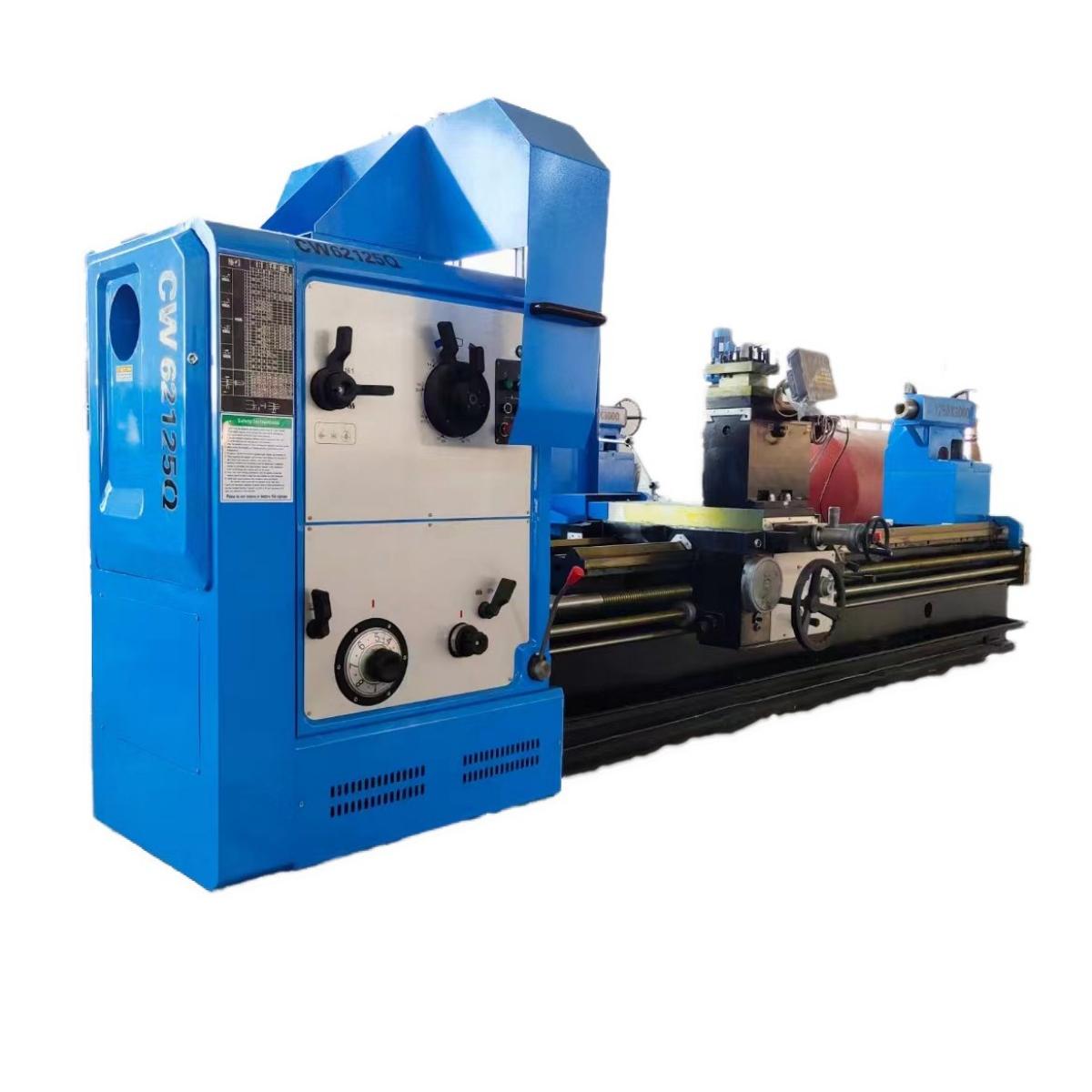

The CK6150 CNC lathe machine embodies Liyang Machinery’s commitment to engineering excellence. Designed for mid- to high-volume production, the CK6150 features a robust cast-iron frame, rigid bed structure, and precision linear guides, ensuring stability and vibration-free machining even under heavy loads. Powered by advanced CNC controllers (compatible with Fanuc, Siemens, or GSK systems), the lathe delivers sub-micron accuracy, repeatability, and rapid tool changes, making it ideal for turning complex components such as shafts, bushings, and hydraulic fittings.

What sets the CK6150 apart is its dual spindle configuration—a game-changer for high-efficiency manufacturing. By integrating two synchronized spindles, the lathe enables simultaneous operations: one spindle handles roughing while the other performs finishing, or it allows for part transfer between operations without manual intervention. This capability slashes cycle times by up to 50%, reduces labor costs, and minimizes human error, making the CK6150 a favorite in automotive, aerospace, and medical device industries.

As a CK6150 CNC lathe manufacturer, Liyang Machinery combines cutting-edge design with rigorous quality control. Its China-based production facilities leverage advanced CNC machining centers, robotic welding, and precision assembly lines to ensure every lathe meets ISO 9001 and CE standards. Liyang’s engineering team continuously innovates, integrating features like live tooling, C-axis milling, and bar feeders to expand the CK6150’s capabilities, transforming it into a complete turning-milling center.

For clients with unique requirements, Liyang Machinery excels as a custom CNC lathe supplier. Recognizing that no two workshops are alike, the company offers tailored solutions to optimize performance. Whether clients need a custom spindle speed range (up to 6,000 RPM), extended Z-axis travel for longer workpieces, or specialized hydraulic chucks for delicate materials, Liyang’s R&D department collaborates closely with buyers to refine specifications. The company also provides custom software interfaces, tooling packages, and automation integration (such as robotic loading systems) to align the CK6150 with existing workflows.

Liyang Machinery’s China-based advantage extends beyond manufacturing. By optimizing supply chains and leveraging economies of scale, the company delivers CK6150 CNC lathes at competitive prices, enabling clients to upgrade their capabilities without breaking the bank. Its global logistics network ensures timely delivery, while on-site installation, operator training, and 24/7 technical support guarantee a seamless transition to production.

Sustainability is also a priority for Liyang Machinery. The CK6150’s energy-efficient servo drives, coolant recycling systems, and low-noise operation reduce environmental impact, aligning with global trends toward green manufacturing.

In conclusion, the CK6150 CNC lathe machine from Liyang Machinery is more than just equipment—it’s a strategic investment in productivity and precision. As a China-based manufacturer and custom CNC lathe supplier, Liyang empowers businesses worldwide to tackle complex turning tasks with confidence, whether through standard models or tailored solutions. Partner with Liyang Machinery to unlock the full potential of your manufacturing operations, where Chinese engineering ingenuity meets global industrial demands.